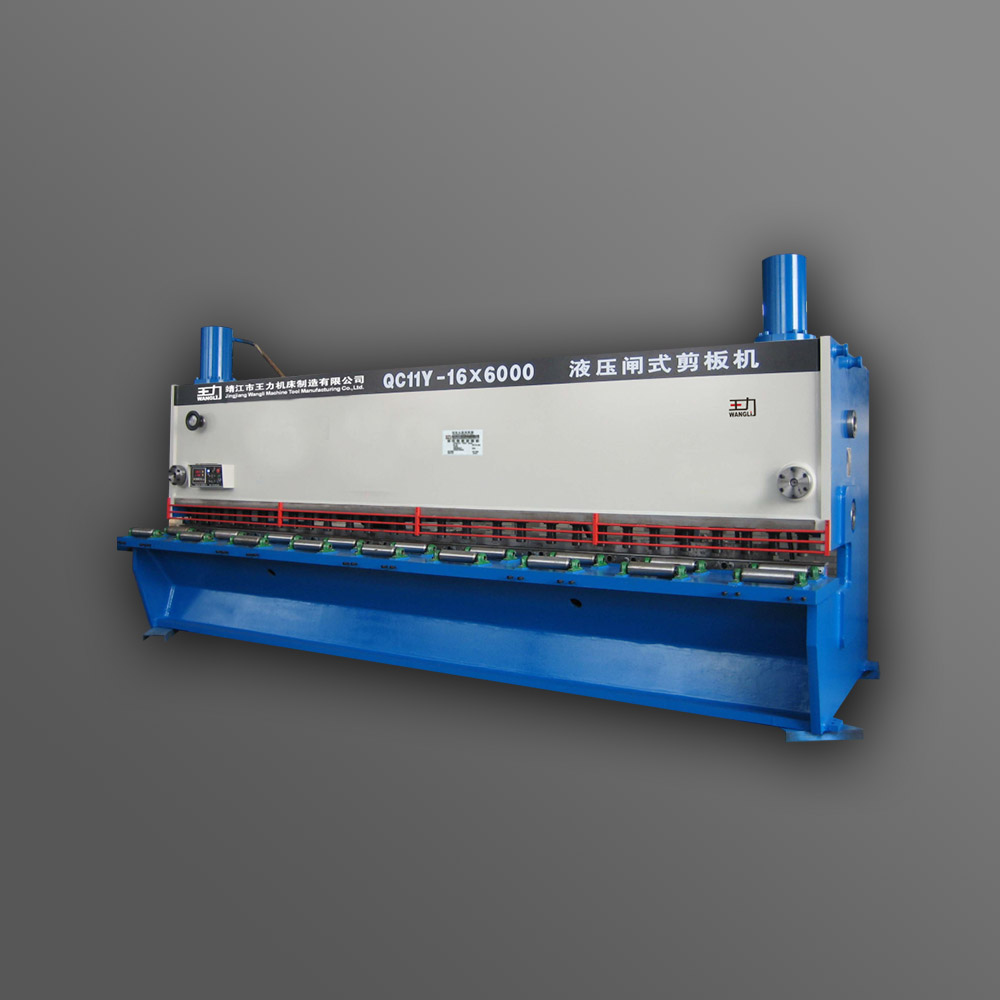

- The machine adopts steel-welded structure, eliminate the stress by vibratory stress relief to keep static state, dynamic rigidity.

- It adopts the advanced integrated hydraulic system, which features good reliability;

- It adopts three-point supporting rolling guide to eliminate the support clearance, so that to improve the shearing quality.

- Motor-driven back gauge, with manual fine adjustment and digital display.

- The blade clearance is adjusted by hand wheel; fast, accurate and convenient.

- Rectangular blade, with four available cutting edges, long service life. The cutting angle is adjustable, so that to minimize the distortion of sheet.

- The upper blade adopts internal inclined structure to facilitate loading materials and to improve accuracy.

- It has the functions of sub-shear and lights on the line.

- Back support device is for option.

Technical Data

| Model |

6 x 6000 |

8 x 3200 |

12 x 2500 |

12 x 3200 |

12 x 4000 |

16 x 2500 |

16 x 3200 |

16 x 4000 |

20 x 4000 |

| Max. shear thickness |

6 |

8 |

12 |

12 |

12 |

16 |

16 |

16 |

20 |

| Plate strength (N/mm2) |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

| Max. shear width of plate |

6000 |

3200 |

2500 |

3200 |

4000 |

2500 |

3200 |

4000 |

4000 |

| Shearing angle |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

1°30’ |

| Max. distance of back gauge |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

| Power of main motor (KW) |

11 |

15 |

18.5 |

18.5 |

18.5 |

22 |

22 |

22 |

30 |

| Overall dimensions L x W x H (mm) |

6400 2750 2200 |

3880 1810 1620 |

3245 2210 2005 |

3950 2270 2005 |

4765 2370 2005 |

3300 2440 2400 |

4050 2440 2050 |

4850 2440 2300 |

4890 3000 2910 |

| Weight of machine (kg) |

21000 |

8320 |

9600 |

11000 |

13270 |

11500 |

14000 |

18500 |

26600 |