Series Q35Y Hydraulic Ironworker

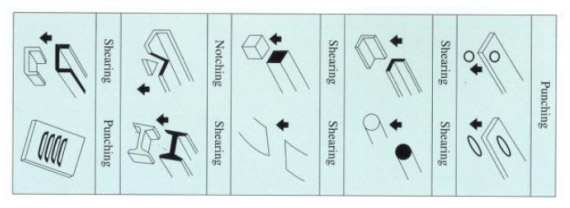

They adopt hydraulic driving system and they are the latest iron workers in our country,Various metal plate,squarebar,Round bar, angle, channel and joist can be cut, punched and notched on the machine.It is also equipped with a stop device for cutting.

Technical Data:

| Model |

Q35Y-16 |

Q35Y-20 |

Q35Y-25 |

Q35Y-30 |

Q35Y-40 |

Q35Y-50 |

Q35Y-60 |

| Pressure |

60T |

90T |

120T |

160T |

200 |

250 |

300 |

| Max cutting thickness(mm) |

16 |

20 |

25 |

28 |

33 |

38 |

42 |

| Plate strength(N/mm2) |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

| Cutting angle |

7° |

8° |

8° |

8° |

8° |

8° |

8° |

| Shearing size of one stroke |

16×250 8×400 |

20×330 10×480 |

25×330 16×660 |

28×355 20×600 |

33×400 25×600 |

38×400 20×600 |

42×400 20×600 |

| Ram stroke(mm) |

80 |

80 |

80 |

120 |

120 |

120 |

120 |

| Number of stroke(80) |

8 |

8 |

6 |

6 |

6 |

6 |

6 |

| Number of stroke(20) |

25 |

25 |

16 |

16 |

12 |

12 |

10 |

| Throat depth(mm) |

300 |

355 |

400 |

600 |

450 |

450 |

450 |

| Punching thickness(mm) |

16 |

20 |

25 |

28 |

33 |

38 |

42 |

| Max punching diameter(mm) |

25 |

30 |

35 |

38 |

40 |

40 |

40 |

| Power of main motor(kw) |

5.5 |

7.5 |

7.5 |

11 |

15 |

15 |

18.5 |

| Overall dimensionsL×W×H(mm) |

1640×730×1770 |

1860×800×1900 |

2355×960×2090 |

2600×1040×2300 |

2700×1350×2400 |

2800×1450×2500 |

2980×1550×2600 |

| Weight of machine(kg) |

1600 |

2000 |

4000 |

6000 |

7500 |

8800 |

10000 |

Remark: Joist and Channel blades need to order specially

| Profile |

Round Bar |

Square Bar |

Equal Angle |

T Bar |

Joist |

Channel |

||

|

90° Shearing |

45° Shearing |

90°Shearing |

45°Shearing |

|||||

| Section view | ||||||||

| Q35Y-16 |

45 |

40*40 |

125*125*12 |

50*50*5 |

125*75*12 |

60*60*8 |

126*74*5 |

126*53*5.5 |

| Q35Y-20 |

50 |

50*50 |

140*140*12 |

50*50*5 |

140*90*12 |

70*70*10 |

160*86*6 |

160*60*6.5 |

| Q35Y-25 |

60 |

50*50 |

160*160*14 |

60*60*6 |

160*110*14 |

80*80*10 |

200*102*9 |

210*75*9 |

| Q35Y-30 |

65 |

55*55 |

180*180*16 |

60*60*6 |

180*120*16 |

80*80*10 |

280*124*10.5 |

280*86*11.5 |

| Q35Y-40 |

70 |

60*60 |

180*180*16 |

60*60*6 |

200*130*16 |

100*80*12 |

300*128*11 |

300*87*13.5 |

| Q35Y-50 |

75 |

65*65 |

180*180*16 |

60*60*6 |

240*135*18 |

120*80*12 |

320*132*11.5 |

320*90*14 |

| Q35Y-60 |

80 |

70*70 |

180*180*16 |

60*60*6 |

280*140*18 |

140*80*12 |

360*138*12 |

360*11*16 |

Products Station

|

||

| positioning of back stopper backgauge supplied as require equipment.Fine adjustment allows for precision cuts.Fully protected harness for safety and reliability.Large contact button for maximum productivity. | Punching StationLarge viewing window on stripperSwing away design for ease of operation。Largetwo piece gauging table with rulers and stop as standard equipment。Quick change coupling nut and sleeve for rapidreplacement or change | Notching Station:Unique design allows for unsurpassed cutting of angle and flat bar.Electrically interlocked safety guad for maximum operator safety.Ventilated guard for maximum operator visibility.Three guaging stops for precise positioning. |

|

||

| The angle iron shear has the ability to cut angleiron at 45 degrees both top and bottom leg.This gives the operator the ability to make a picture frame corner for perfect weild. | Flat Bar Shearing Station Easily adjustable hold down with good operatorvisibility for accurate cutting.Large 15″ squaring arm with inlaid scale as standard equipment. | Specially contoured anti-distortion blade forquality cuts.Lower blade has four usable edges.Allen head set screws allow for easy gapping of the machine.No shimming is required. |

|

||

| Punching StationFull range of universal punches and dies are available。Unique style allows for large angle iron punching and large channel punching | Diamond shaped blade for quality cuts and nomaterial loss with minimal deformity.Forty five degree miter cut both top and bottom leg for a picture frame comer. | Round and Square bar shear has multiple holes for a variety of sizes.Adjustable holdown for clean square cutting.Optional Channel and beam shears available. |

|

||

| Large heavy duty knobs Precise square bar cutting |

Large strong guarding for maximum safety | Mitering with large standard squaring arm |